There are numerous programs that enable you to design parts, signs, artwork, or anything else that can be made on a CrossFire CNC. If you are just getting started, we recommend choosing a Ready-to-Cut project from FireShare to start. Select the geometry tab, and change the Matching Boundary to Silhouette.The first step in creating parts for the CrossFire is designing or using previously designed projects. It’s too easy to break the tool otherwise.

Set the feed rates for the operation, I dial these ways back to 100 mm/min for my little mill on acrylic. Now that we have Set up our drilling tool, we press Select.

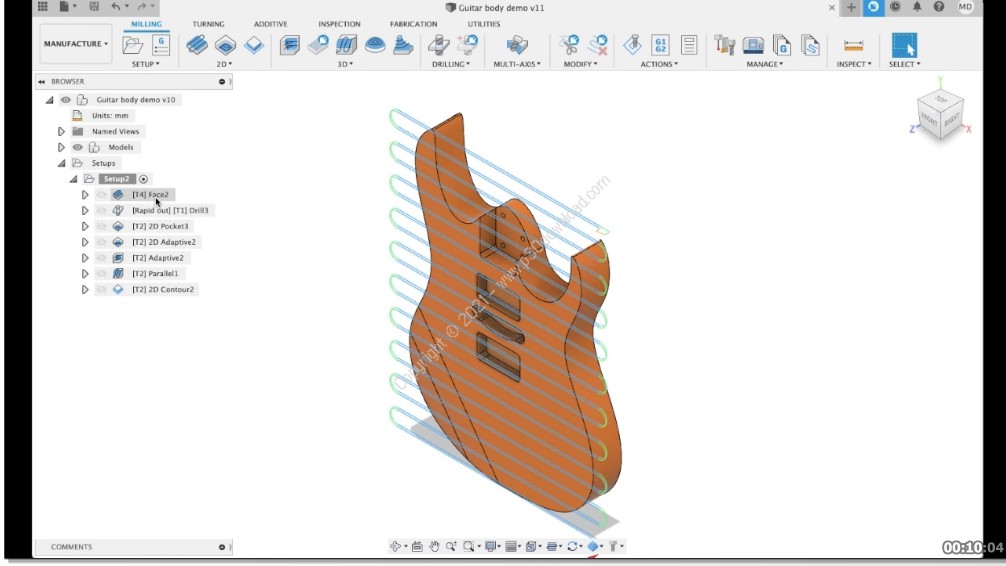

Press Accept when finished entering the details. Those helical troughs that spiral up the side. The only that might not be obvious is ‘Number of flutes’, a flute is the channel in the side of the bit. I used a set of digital calipers to make all the measurements. Select the cutter tab and fill out all the details for the milling bit you are going to use. In the General tab, you can fill in whatever you want. Once again, a new window opens called New tool. Select the 3D menu and press Pocket Clearing.Ī new window opens, press the blue plus sign. The first is to clear out all the holes in the piece, some of these are countersunk, so we will use ‘pocket clearing’ for this. Now we are ready to start giving actions for our CNC mill to perform.

Set the top offset to 0 mm (assuming we will be cutting this from material that is the same thickness as the part) and press, OK. Select Box Point to select a stock point to be the origin for our job.Ĭlick the left upper point on the top of the yellow semi-transparent stock box.īump the side offset up by to 5 mm, to give us a bit of a margin when cutting the part. We need to define the Z-Axis, we do so by clicking on the side of the model (the white marked in the picture).Īs you can see in the picture below, the Z-Axis is now pointing up. Select the button with the arrow behind A-Axis. In the Setup tab, select the orientation drop down and click Select Z axis/plane & X axis. Select the SETUP menu and select New Setup. We need to set the coordinate system such that the Z-axis points up, while the x and y-axis from the plane matching the top of the stock (the yellow semi-transparent box). Most importantly, it lets us set up how our stock will be orientated in our mill. It lets us tell Fusion a few details about the stock, or the material we will be using to cut the part from.

A setup holds general properties about the milling job.

0 kommentar(er)

0 kommentar(er)